The idea is to have a thermal storage battery where to dump extra energy produced by the solar panels that does not fit into the lithium battery. Otherwise this extra energy produced by the panels is simply wasted. The stored thermal energy during the day can then be used to heat a space during the cooler night.

Insulated container to keep the thermal storage medium. This can be a cooler. The thermal storage medium can be water or possibly paraffin wax (if planning to use phase change).

12V immersion electric heater and thermostat. An electric element to heat the storage medium.

The thermostat prevents the heat in the storage medium to go above a set limit.

Storage 12V relay. Apparently the Victron battery monitor can control a relay depending on the state of charge of the lithium battery. This relay then would be used to activate storing energy in the thermal battery when the state of charge is above a set threshold.

Radiator, 12V fan and 12V water pump. These components will take heat from the storage medium, heat water and then pump the water through the radiator to expel heat into the space desired to be heated. If the storage medium is not water then a heat exchanger is needed between water in the radiator circuit and the storage medium; a copper coil would do.

14/Aug/2019

The solar panels are rated at 300W, and after losses and non-optimal sun orientation maybe 200W output. Thus once the batteries are charged the most likely surplus would be around 200W, or even just 100W if we use a conservative estimate.

Thus, what we want is a water heater that uses 100 to 200W. Hopefully with self contained thermostat, submersible and ideally 12V operated. Aquarium heaters fit the bill, but their thermostats only go to about 30C. We need a thermostat that goes close to boiling.

This 12V 150W water heater looks good: link

Maybe this tank can be rewired to use the above heating element. Hmm maybe not it uses line voltage for it's controls: link

My Renogy charge controller can deliver 20A on the 'Load' terminals. Assuming is at 12V that's 240W. Does not work: the 'Load' terminal cannot be programmed to be 'ON' when the batteries are charged, so it's useless for this project.

Here's a thermostat controlled relay: link

To control heating the water, and later circulating the heater water to heat the air.

Here's a water pump: link

Heated water can store 88Wh per liter: link

Assuming 90C heated water, and 15C room temp.

We estimate the solar system's energy is wasted for 5 hours of the day because the batteries are already charged. If we assume 100W being produced during those 5 hours, that's 500Wh needed to be stored. Using the capacity of water energy storage calculated above, we'd need about 6 liters of water (1.6 gal). We could store a 1000Wh in approx 3 gal of water.

500W for an hour would provide some heating for the van. But double that would better.

The 100Ah lithium battery currently in the van can store 1200Wh of energy.

The water tank could be a regular rectangular cooler. There are drink coolers, but they are vertical and likely don't fit under the van's bed.

Detecting that the battery is full is easy because it reaches a certain voltage, 14.4 V or something like that. Here's a voltage controlled relay board that could work: link

Even when there's a load on the battery it will still maintain a voltage > 14V if there is enough sun on the panels.

Parts to heat the van using hot water:

The only thing that I can't find is a 12V water heater that can be dipped in the cooler from the top. The best candidates are the ones that get screwed on the side of the tank.

This kind of heater would be useful in the summer (and shoulder seasons) in areas of the US where the max in the day gets between 25 C and 30 C but in the early morning it can be as cold as 11 C to 15 C.

26/Aug/2019

Wikipedia: Thermal energy storage

Water has one of the highest thermal capacities (heat capacity per unit of mass), but other materials can be heated to much higher temperatures and not turn to gas. Thus alternative materials (e.g. concrete, rock pebbles) can have much higher volumetric capacity. For the van we probably care about weight the most, so water is the best.

Phase change materials are interesting, but too complicated to use, plus they have specific temperatures at which energy can be put in or taken out. We need a material that can release heat to room temp of 0 C to 20 C.

A well implemented energy storage in water would be to buy a small electric water heater and change the heating element for a 12V one, keep the same thermostat.

A campervan needs a fresh water storage tank anyway, so insulating it and heating it to store heat energy it does not add much extra weight to the vehicle.

This company has DC water heating products: link

The data module for the solar charge controller could be useful to have data on how much energy the panels are producing.

Hmm, the phone app has really bad reviews. link

Insulated water tank: $0. Use the cooler that I already have for now. Which is 48 qt (I think) = 12 gal = 45.4 liters. Using water heat storage capacity formulas above, 40 liters can store 3.5kWh of heat energy.

Heating element: $23. This 12V 150W (implying: 0.96 Ohm resistance: At 14.4V draws 15A) water heater looks good: link

Connect to 20A fused circuit. Details: link

Heating tube length: 7.5 Inch.

Bulkhead Fitting for Water Heating Element: $4. 1" internal diameter to fit heating element below: link

Hole saw to install the bulkhead fitting: $7: link

Thermostat controlled 12V relay: Needs to support at least 15A relay for the heater unit above. This supports 20A. Get the one with the acrylic case: link

Relay to activate water heating when battery is charged (voltage > 14V): link

27/Aug/2019

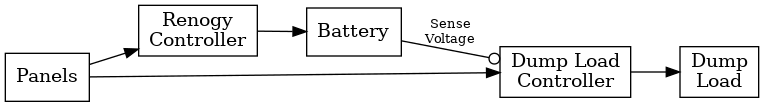

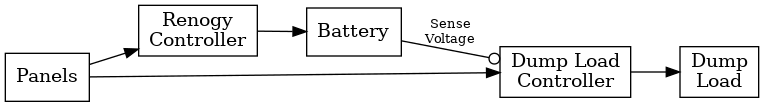

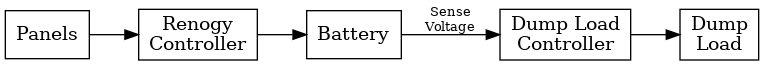

Ideally the amount of power sent to the thermal battery should be adaptably regulated, to be the same as the excess power being produced by the solar panels at any moment. The current solution sends a fixed amount of power to the thermal battery, which is determined by the resistance of the heating element. An adaptive power controller would start with an output voltage of zero volts, then increase the output voltage, perhaps using PWM, until the battery voltage lowers to the trigger value (e.g. 14V). The circuit needed is called "Dump Load Controller".

A possible arrangement of a dump load controller, see below. The direct voltage from the solar panels is sent to the dump load through a relay. This relay is controlled by sensing the battery voltage and triggering when the voltage is above a threshold (e.g. 14V). A fuse should be used to not draw from the panels more current than they are designed to provide.

My best guess is that these are my 100W panels: link

It seems that extracting maximum power from the panels is complicated (see more info later below). It's better to implement the arrangement below, and let the controller take care of the issue. The "Dump Load Controller" below is simply a voltage controlled relay that connects the dump load when the battery voltage is above a threshold.

The only issue I can see is that if the dump load is too big (in watts) the battery voltage will drop too quickly and the dump load will be disconnected. This can maybe lead to the dump load relay being switched too frequently. Maybe in the future a solid state relay could be used and the switching done fairly quickly.

Information on how to match heating element resistance to panels for direct connection: link

Calculator spreadsheet: link

My panels have these specs:

Direct connection of heating element to the panels only works well when the panels are producing max output, otherwise an MPPT controller is needed to get the most out of the panels.

11/Sep/2019

The relays on the thermostat and the battery voltage controller circuits get too how when powering the 12V 150W (13A) heating element. Solution:

Get a relay capable of 12V 30A. This is the typical automotive relay, get it from an auto parts store.

The cheap extension cord been used as a disconnect also gets hot. Solution:

Get a disconnect plug capable of 12V 30A.

The heating element might be too demanding for the amount of extra solar power. This is yet to be verified, by running the heater during several days.

13/Sep/2019

PROBLEM 1

With the heating element at the top of the tank the water temp stratifies and only the top part gets hot.

SOLUTION 1

Put the heating element at the bottom of the tank.

Also put temp sensor at the hottest part of the water, the top of the tank.

PROBLEM 2

Voltage drops from 14.3V to 12.9V (that is 1.4V), from voltage at the battery to voltage at the electronics box. This means a lot of power is being dissipated by the power cord.

Also, this confuses the circuit looking at the input voltage to decide if the battery is charged or not.

ANALYSIS 2

Voltage across the heating element is 12.45 V when circuit is powered at 12.9 V.

Since the heating element's resistance is ~1 Ohm, the current in the circuit is 12.45 A.

The power dissipated by the heating element is: 155 W. The power dissipated by the rest of the circuit in the box is: (12.9 V - 12.45 V) * 12.45 A = 5.6 W.

The power dissipated by the power cord from the battery to the electronics box is: (14.3V - 12.9V) * 12.45A = 17.4 W. This implies a resistance of: R = V^2 / P ~= 0.1 Ohm.

The resistance of gauge 10 is 1 Ohm/1000ft versus 2.6 Ohm/1000ft for gauge 14.

A 10 gauge power cord would have a resistance of 0.1 Ohm / 2.6 = 0.04 Ohm.

Assuming the same current 12.45A the voltage drop would be 0.5V power dissipation 6.2W.

SOLUTION 2

To reduce wasted power: use a thicker gauge of power cord. Shorten the power cord as much as possible.

To give the circuit a reliable battery voltage measurement: use a second smaller gauge cord to power the electronics; or simply adjust the voltage threshold setting to account for the voltage drop on the power cord.

10 AWG wire on for the power cord is good.

For the battery voltage reference use small gauge (16?) two conductor wire (pos and neg). Use standard 12V plug to connect to power.

PROBLEM 3

The automotive relay gets somewhat hot.

ANALYSIS 3

The automotive relay switch has a voltage drop of 0.034 V when closed. Assuming 12.45A, it dissipates 0.4 W.

The automotive relay coil has a resistance of 111 Ohm. When energized at 14.4 V it passes 130 mA. It dissipates 2 W. Adding the dissipation above the total is 2.4 W.

SOLUTION 3

Do nothing, it's not that bad.

The relay gets hot because of continuous operation of the coil, not because of passing current.

PROBLEM 4

Panels cannot supply extra 150W of power at latitude 45 deg and in the month of September.

They can only supply 100W.

SOLUTION 4

Get a heating element with less power. Or get another one of the same type and connect them in series. A controller+relay or manual switch could be used to short one of the elements and thus have two power levels to select from, and adjust according to panels power output.

Ordered a less powerful heater. Plus it's made of many 12W units, so it's easy to adjust power as needed.

PROBLEM 5

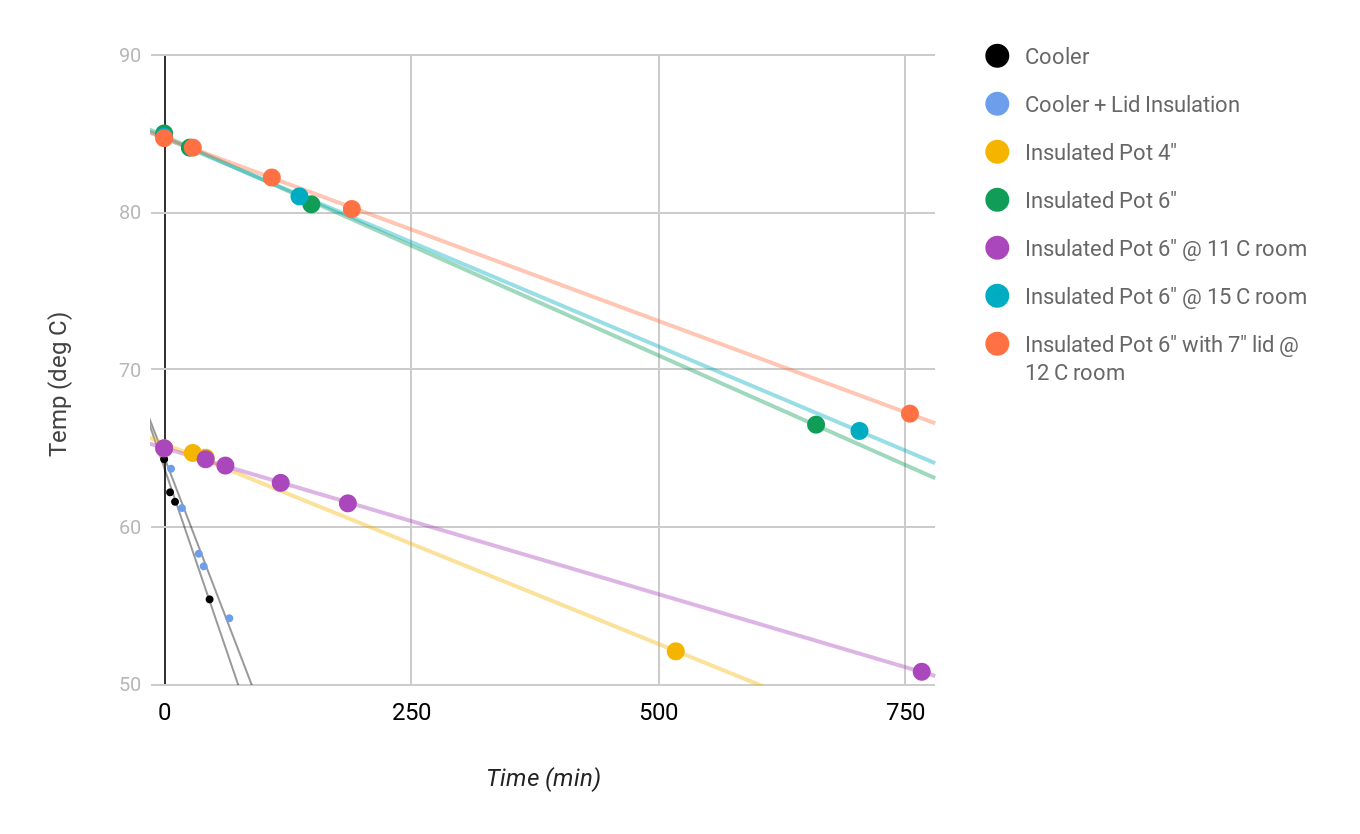

The drink cooler's lid is not insulated. And in general the cooler is not very well insulated. Causing a quick loss of water temperature.

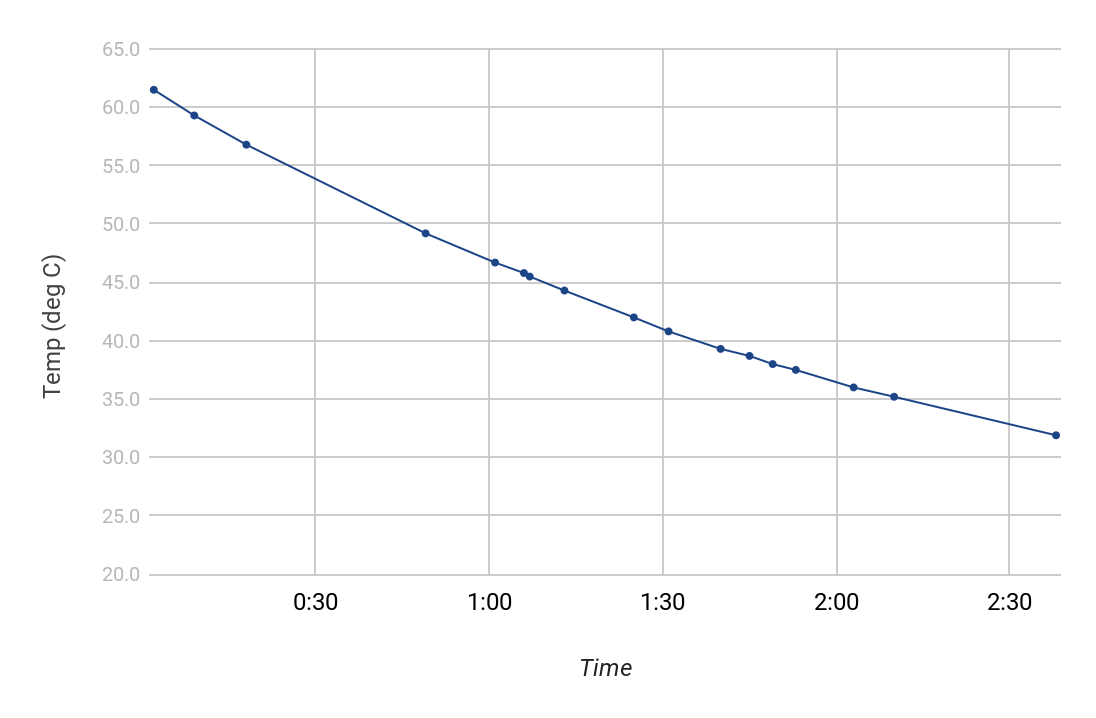

Room temperature 25 C, for the table below:

| Time | Temp | Delta Temp | Delta Time (min) | Delta Temp / Time (deg/min) |

| 15:13 | 64.3 | -- | -- | -- |

| 15:19 | 62.2 | -2.1 | 6 | 0.35 |

| 15:24 | 61.6 | -2.7 | 11 | 0.25 |

| 15:59 | 55.4 | -8.9 | 46 | 0.19 |

SOLUTION 5

Ideas: Insulate the lid: It did something, see graph above.

Ideas: Use get a better cooler. Or use a domestic water heater (expensive).

Investigating using a water heater:

Better solution is to get my own water container, add insulation to it, and bulkhead fittings as needed.

PET plastic can go up to 150 C.

Maybe an aluminum pot? Seems like it would be more expensive than a plastic container.

Keywords: Drums, Barrels. Maybe beer keg?

Here's a good option:

Here's a 5 gal metal bucket with lid: link

Standard paint cans are 1 gal.

Well insulated chest coolers at $75 for 7 gal. size.

Marine coolers are a cheaper option: link

$75 cooler: link

With threaded drain plug. Dimensions: 46 x 34 x 34 cm Capacity 4 gal.

Water heater expansion tanks are about $30. And come in 2 gal size. Only problem is that it's hard to access their inside to screw the heater element nut.

Interesting design:

Glue the resistors to the tank with thermally conductive adhesive.

PTC heating element seems like a good idea. They self limit the temp.

Possible plastic tank materials:

14/Sep/2019

I'm liking the solution of using an 8 qt (2 gal) stainless steel pot ($10 at Walmart): link

Also look at the 16 qt (4 gal) one. Almost the same price. It's the wall might be flatter and thus don't need hammering: link

Lots of good examples in YT: "DIY super insulated cooler".

This element can be placed on the outside of the pot. 8 of them make up 96W: link

15/Sep/2019

PROBLEM: The automotive relay gets hot when continuously activated.

ANALYSIS: Look into alternative relays. I can't see any good alternatives. It seems it's normal for relays to get hot.

16/Sep/2019

It would be useful to have a voltage and current monitor and logger to measure how much energy is put into the thermal battery. For example: link

19/Sep/2019

Using the 48W heaters (specified at 12V, each should be 12 Ohm and in parallel 3 Ohm), at 13.7 V they pass 3.7 A (yielding ~3.7 Ohm), using 50.7 W.

With two banks of heaters the max current would be ~8 A, I could use gauge 12 for the power cord and be ok: link

To power a single bank gauge 14 is fine.

Maybe with the lower power heaters the car relay is not needed. And the inefficiency of the heat wasted by energizing its coil can be avoided.

Using two voltage sensor controllers set at slightly different threshold voltages and each controlling a bank of heaters it's possible to arrange a system that automatically adjust how much power to request from the solar panels.

23/Sep/2019

The insulated pot (4" of Polyiso) looses 10 deg in 400 min, starting at 65 C. That's a big improvement over the temperature loss of the cooler; see graph above.

24/Sep/2019

Altitude has to be taken into consideration to avoid the water from boiling. The highest the van is likely to be is 3000 m. Using the table below, 85 C seems like a safe setpoint: link

Thermostat circuit settings: Long press on 'set' button to set parameters P0P7:

25/Sep/2019

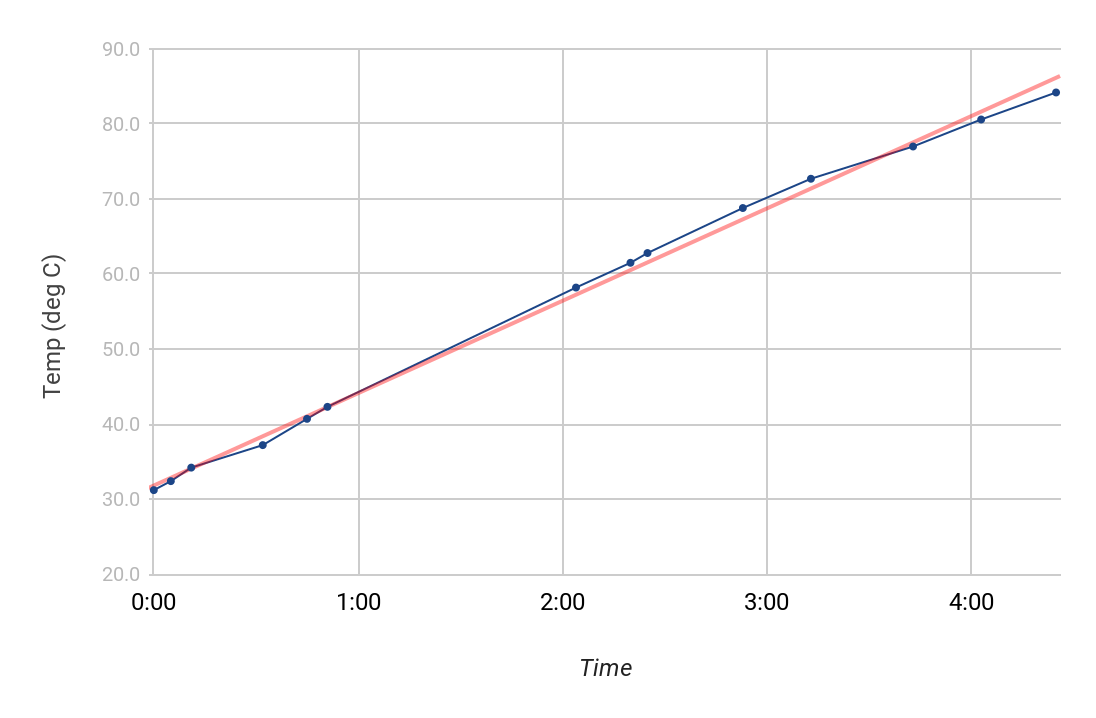

With the pot insulated with 6" of polyiso: Water heated to 85 C at 18:40 and left overnight reached 66.5 C at 05:40 (see graph above). That's a loss of 18.5 C in 11 hours, 1.7 C per hour. Assuming a 10 C room temp, about 25% of the heat energy is lost overnight.

Heated water can store 64Wh per liter; assuming 65C heated water, and 10C room temp: link

Assuming the pot holds 7 liters (1.85 gal). That's 448 Wh.

There's about 20 kg of air in the back of the van. The specific heat of air is ~1 kJ/kg. Using the same formula as for energy storage of water, but raising the temp of air from 10 C to 20 C, the energy needed is: ~56 Wh. That's assuming that none of the energy is escaping from the van to the outside, which is not true.

26/Sep/2019

With the pot insulated with 6" of polyiso: Water heated to 65 C at 17:37 and left overnight reached 50.8 C at 06:24 (see graph above). That's a loss of 14.2 C in 12.8 hours, ~1.1 C per hour.

Previously with the pot insulated with 4" of polyiso: Water heated to 65 C and left overnight reached 52.1 C after 518 minutes (see graph above). That's a loss of ~1.5 C per hour. That's a 36% increase in the heat loss over the 6" insulated pot.

27/Sep/2019

The configuration with 8 x 12 W (nominal) heaters and 12 AWG power cord, draws 7.44 A at 13.96 V; which is approx. 104 W, each heating element producing about 13W.

Added one more layer of 1" insulation to the lid. I does make a visible difference on heat loss, see graph above.

28/Sep/2019

This graph shows the loss of temperature due to the fan blowing on the side heatsink is activated; with room temp ~11.7 C.

Based on the data from the graph above: the pot released 216 Wh in 2 hours, meaning 108 W per hour. This had absolutely no effect in heating the van in the morning.

The pot can only reasonably go down to 30 C not really to room temperature. So making things simple, the starting temp is 60 C and the final temperature is 30 C, a difference of 30 deg C, which using the energy storage in heater water formula (see above) gives a total energy releasable by the pot of: 245 Wh.

The graph below show the gain in temp as the pot is heated using solar power during the day. The temp change rate is approx. 50 deg C in 4 hours; 12.5 deg per hour. Using the energy storage in heater water formula (see above) that comes up to 102 W per hour. Which is pretty damn close to the power the heaters are adding to the water.

The Mr. Heater Portable Buddy Propane Heaters that I own puts out 1172 W in low setting and 2637 W in high setting. The low setting is not quite fast enough to heat up the van in the morning. A reasonable power target for a heater would be 2000 W.

It's possible that the low setting for a whole hour would bring up the van temp to a reasonable level. That would mean about 1200 Wh of energy is needed to heat up the van in the morning.

A 7 liter pot can provide 245 Wh (see above), that means 35 Wh per liter. That means 34.3 liters (~9 gal) are needed to satisfy the 1200 Wh energy requirement.

A volume of 35 liters is enclosed by a cube of side size 33 cm. That cube also needs 7.62 cm (3") of insulation on all faces, which adds 15.25 cm to the length of each side of the cube. The resulting cube's side is 48.25 cm long or approx 50 cm.

Such a cube with 35 liters of water would require 2246 Wh to go from 30 C to 85 C. That's 22.5 hours of solar power at 100 W. But we determined that there's at most only about 5 hours of available extra solar power at 100 W per day. So heating such a cube would require 4.5 days.

The pot of 7 liters goes from 85 C to 65 C overnight due to heat loss. That's an energy of 165 Wh. The lithium battery has a capacity of 100 Ah, at 12V that's 1200 Wh. The energy required to keep the pot hot overnight it approx 15% of the battery's capacity. Maybe worth it. Though that energy has to be recovered from the solar panels the next day, that's an extra 1.6 h. There might not be enough solar to charge the battery and the pot. It's close.

If the pot was kept hot at 85 C until the morning, the energy in the 7 liter pot would be 410 Wh assuming the min temp of the pot is 30 C and the max starting temp is 80 C.

Heating 7 liters from water from 30 C to 85 C is 450Wh, plus the 165 Wh to keep it warm overnight, gives a total of 615 Wh to get 410 Wh worth of van heating. Assuming 100 W of solar, that 6.15 hours of solar for every 410 Wh of heating. Given that we estimate 1200 Wh are minimally needed to heat the van, that's approx 18 hours of solar needed for one day of van heating. Given that we estimate there's only 5 hours of available solar a day, that's 3.6 days of solar for each day of van heating.

After many calculations I determined that: there are about 5 hours of free solar a day at 100W, that's 500 Wh of energy. But to heat the van about 1200 Wh are needed. The water heat storage leaks energy overnight: About 55% of the energy put in can be extracted in the morning. Thus to get 1200 Wh of heating we need 2182 Wh of energy put into heating the water. That's 22 hours of solar or 4.4 days. So I could heat the van one day of 5 (about). Finally about 35 liters of water would be needed to store that energy, which with insulation gives a cube of 50 cm a side.

So the root problem is that I do not have enough surplus solar to heat the van a single day. The problem is made worse by the big losses of energy of storing heated water overnight. If there were no losses I would still need 2 times the amount of solar I currently have to be able to heat the van. Assuming the second set of solar panels generate 7 hours of surplus 100 W.